Working pressure: 1.0MPa~16.0MPa

With the aim of "survival through quality and development through management", Qirui products are your ideal choice. We will create brilliance with you through high-quality product quality and after-sales service!

The product is widely used in industries such as petroleum, chemical, metallurgy, power, military, papermaking, and new energy.

What are the applications of three piece forged steel ball valves?

The three piece forged steel ball valve is widely used in industrial fields with strict performance requirements for valves due to its split structure, high-strength material, sealing reliability, and extreme working condition resistance. Starting from the core advantages, classify and explain its typical application scenarios and key selection criteria: 1、 High pressure and high temperature working conditions 1. Oil and gas transportation High pressure pipeline: Used for long-distance crude oil and natural gas pipelines of Class 600~2500LB (PN100~PN420), it needs to pass API 6D certification and withstand pipeline pressure fluctuations.

09-30

What is the difference between stainless steel flange ball valve and ball valve

There are some differences in structure and application between stainless steel flange ball valves and ball valves. The following is a specific comparison between the two: 1、 Structural differences Connection method Stainless steel flange ball valve: Connected through flanges, flange connection is a common connection method, suitable for occasions that require frequent disassembly. Ball valve: There are various connection methods, including flange connection, welding connection, threaded connection, and clamp connection, which can be

09-30

Working principle and correct installation method of Y-shaped filter

Y-shaped filter is an indispensable filtration system in pipeline systems, used for transporting fluid media. The following is the working principle and correct installation method of the Y-shaped filter: 1、 Working principle of Y-shaped filter Y-shaped filters are usually installed at the inlet end of pressure reducing valves, relief valves, constant water level valves, or other equipment to remove impurities from the medium and protect the normal use of valves and equipment. The Y-shaped filter has the characteristics of advanced structure, low resistance, and convenient discharge. It mainly consists of a connecting pipe, main pipe, filter screen (filter blue), flange, flange cover, and fasteners.

09-30

Why is a sealing device required for gate valves and globe valves?

Gate valves and globe valves are required to have upper sealing devices, mainly based on the following considerations: 1、 Prevent medium leakage and protect the filling material Prevent medium leakage: When the gate valve and globe valve are closed, the valve stem is in a stationary position. If there is no upper sealing device, the medium may penetrate upwards along the gap between the valve stem and the valve body, causing the medium to leak out. The upper sealing device can effectively prevent medium leakage, ensuring the working performance and safety of the valve. Packing protection: The packing box is usually sealed with flexible materials such as asbestos, polytetrafluoroethylene, etc

09-30

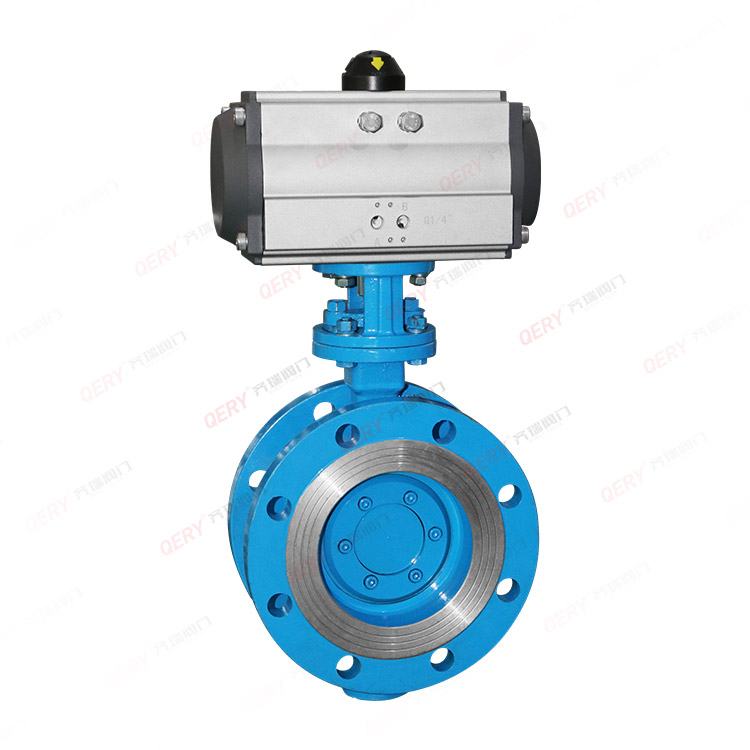

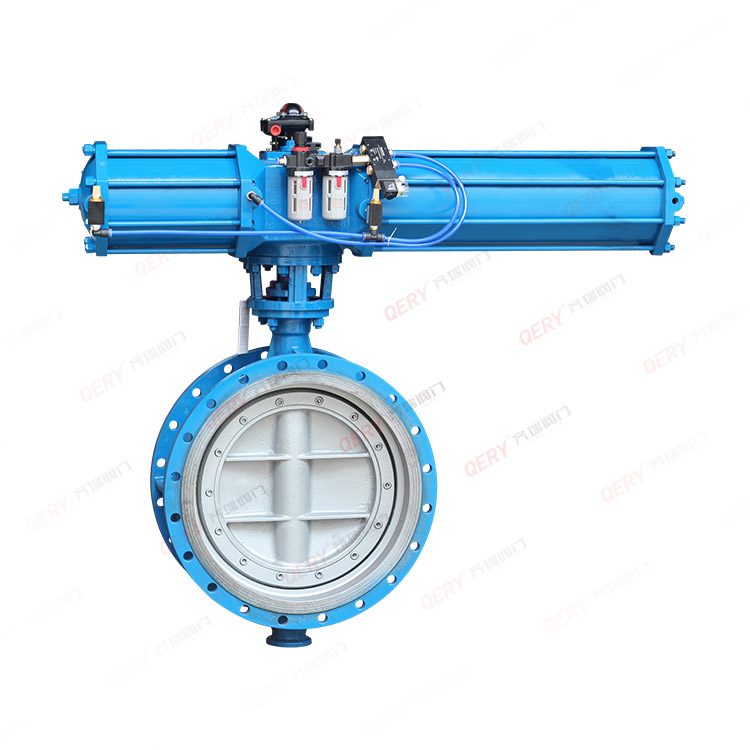

What is the difference between clamp butterfly valve and flange butterfly valve?

There are differences between clamp type butterfly valves and flange type butterfly valves in terms of connection methods, structural characteristics, installation and maintenance, sealing performance, applicable scenarios, cost and price. The following is a detailed introduction: Connection method Clamp on butterfly valve: There are no flanges at both ends of the valve body, only a few guide bolt holes. The valve is clamped between the two pipeline flanges with double headed bolts, and the sealing is achieved by using the clamping force of the clamp flange and the sealing ring. Flange butterfly valve: The valve has flanges at both ends, and the flanges on the valve are bolted together

09-30

Design and structural characteristics of forged steel gate valve

The design and structural characteristics of forged steel gate valves are mainly reflected in the following aspects: Design Features Application and medium adaptability: Forged steel gate valves are mainly used to cut off or connect media in pipelines, suitable for the working pressure range of Class 150~2500, as well as the working temperature range of -29~425 ℃ (carbon steel) or -29~500 ℃ (stainless steel). Different materials can be selected to adapt to water, steam, oil, acetic acid, and oxidation

09-30